Process

My goal with watchmaking was to make a few really great watches without compromise.

The only way to achieve that is to make as much of the watch as possible. Each component affects the rest of the watch and often my designs evolve and get better, even after I’ve finished several prototypes. Moving everything in house allows me to remain flexible in each aspect of the design and continually improve the resulting timepieces.

I’m often asked whether I would consider manufacturing movements. For the time being the answer is no. I think there’s a good comparison to be made with vintage racing cars. Small manufactures sourced engines from large manufactures, and built high performance vehicles around those power plants. I build the best watch components around movements which have are time tested and considered some of the best and most reliable in the world.

I currently design and manufacture cases, case backs, screw down crowns, case tubes, chronograph pushers, dials, hands, movement rings, helium escape valves and automatic rotors. So each component outside of the movement. If that’s not enough for you, check out Josh Shapiro or RGM watches :)

Concept to Design

In my design I draw inspiration from many places, vintage watch designs, childhood memories, the human form, a train trip across France. Through a sometimes months long period of doodling, cad mockups and aluminum prototypes a new watch design emerges.

Function and purpose is paramount in each of my watches. And to highlight these

In my photography work I always found that my best images were the ones made by most effectively using shadow. The absence of light drew the eye to what really mattered. The same philosophy is used with my watch designs.

The dials are stripped of everything not needed for telling time, the cases skip any extra mentions of depth ratings and materials used. If you buy a watch you know those details already.

Cases

My cases are designed and built around the components used and desired durability goals, the gaskets needed for a specified depth rating and a desired dial diameter. Once the dimensional and survivability needs are met, function steps aside as form smooths out the edges and nudges contours to wrap around a wrist and provide a comfortable wearing experience.

I use the best materials available from trusted suppliers. This includes 6al4v titanium, 316 and 8-18 Stainless Steels, NBR, Viton and Silicone gaskets and incredibly durable Sapphire crystals with anti reflective coatings.

Dials

Seemingly a simple part of a watch, a flat surface with some markings painted on.

And then you try to make one of these damn things.

The human eye has a remarkable ability to pick out minor imperfections and the smaller and more detailed what you’re looking at becomes, the more this is true. I spent months trying to get a dial I liked. And then months more making a second, and then a couple of years learning consistency with that.

My dials are different than many. Rather than a simple flat piece of stamped brass, they are machined three dimensional parts which wrap up and around the movement and act as a direct link to the watch case. This design replaces the traditional movement holder which most watches use thus reducing parts, weight and complexity.

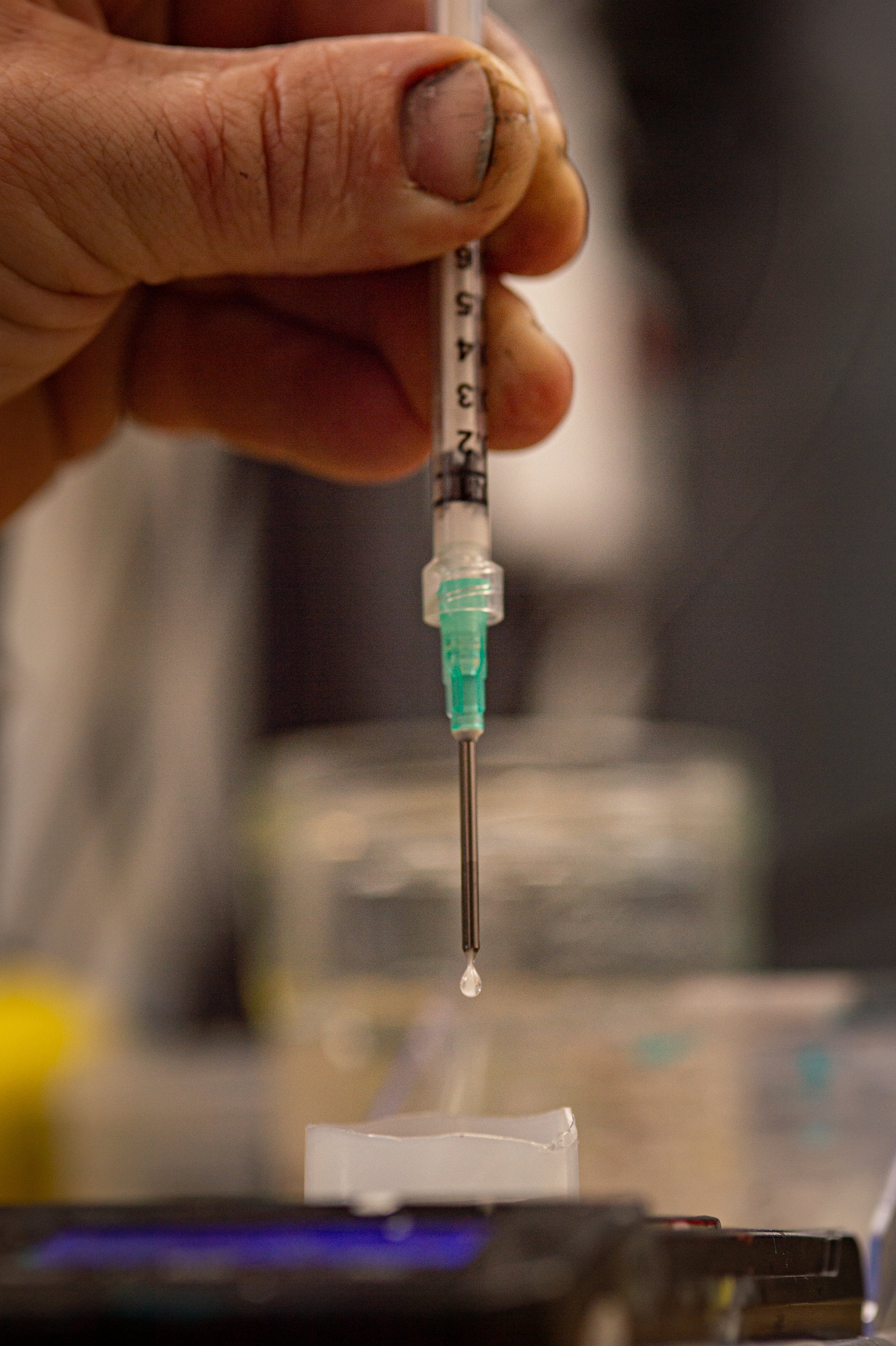

Instead of attached lume indices I’ve opted to machine the dial markings directly into the dial. This gives me a deep well to fill with lume for a brighter, longer lasting glow. And also allows me to move the hands closer to the dial, thereby reducing the overall thickness of the watch.

These dials are then ceramic coated before being pad printed and lume applied.

It’s not the easiest way to do it but I’d like to think the results are worth the headache.

The fonts I use are, for the most part, designed in house. Combining legibility, style and ease of machining is something that was in itself a months long process of trial and error.

Hands

My hands are machined from billet and are one piece designs.* Most of my watches use titanium hands for the light weight and ability to spring back after hard knocks. For designs where a blued steel would be more suitable I use 1095 carbon steel. Finishing options include ceramic coating, lacquer, anodizing or polishing.

*I was referring here to the watch hands. My actual hands are meaty, sausage-fingered lumps which really have no business anywhere near a wristwatches interior.

Crowns

Easily one of the most challenging pieces to manufacture on a watch is the crown. Particularly when making those with the ability to screw down to the case tube. A crown consists of 5 pieces, each machined to exacting dimensions to ensure water resistance.

On my currently available watches the crowns are Grade 5 Titanium triple seal screw-downs All have threaded case tubes which use standard Torx bits for removal.

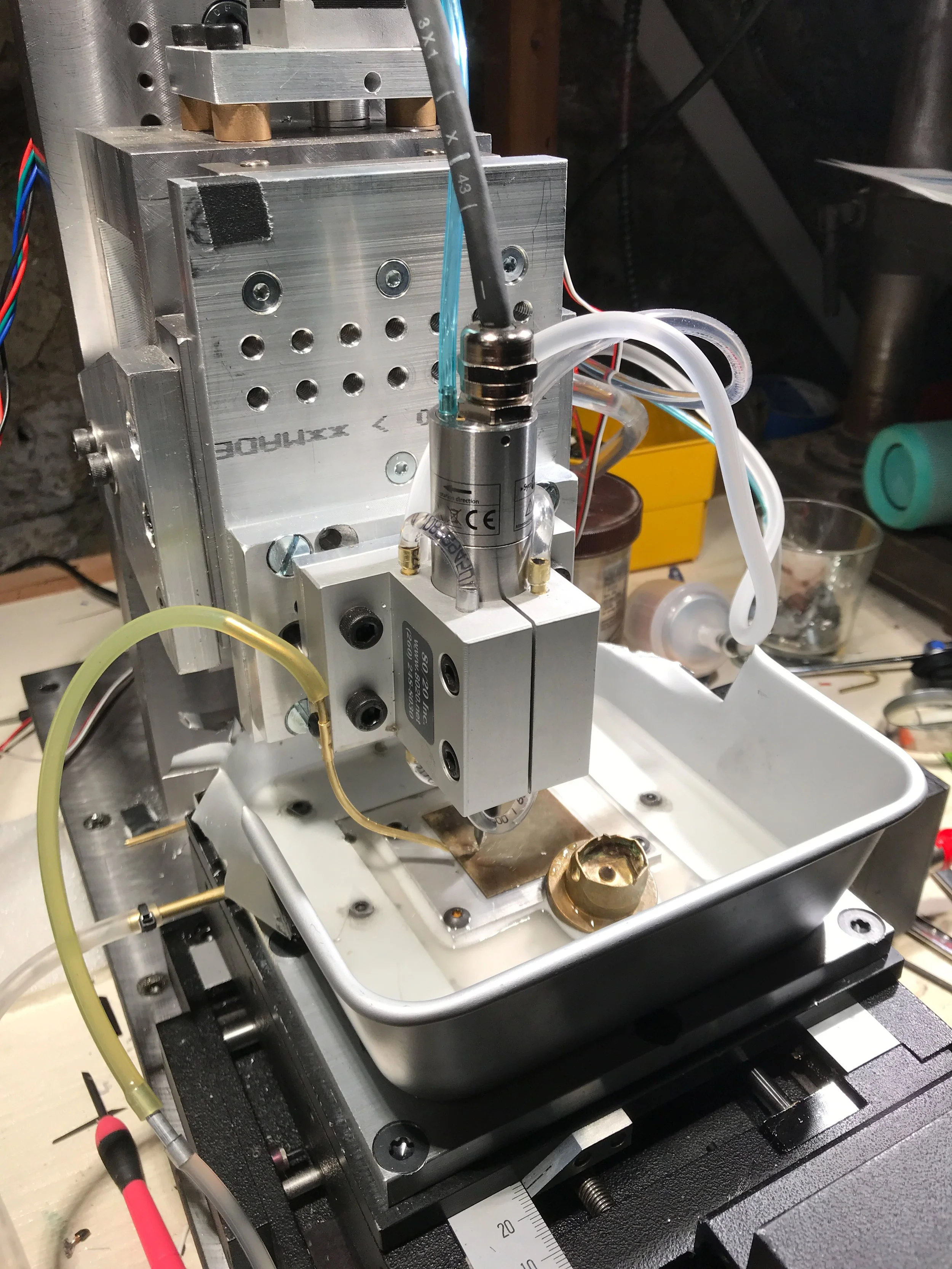

The Machines

My shop is built around two 3 axis CNC machines which I built from scrap steel, surplus parts and a bunch of cussin. The larger of the two has an epoxy granite frame which gives a sturdy platform for cutting titanium and stainless cases, case backs and crowns. The smaller machine sports a 100k RPM spindle and the ability to cut extremely fine details needed for the hands and dials.

I’ve also built a pad printing machine for dials a polishing lathe, a lume injector for hand and dial applications and several drawers full of jigs and fixtures needed to manufacture parts.

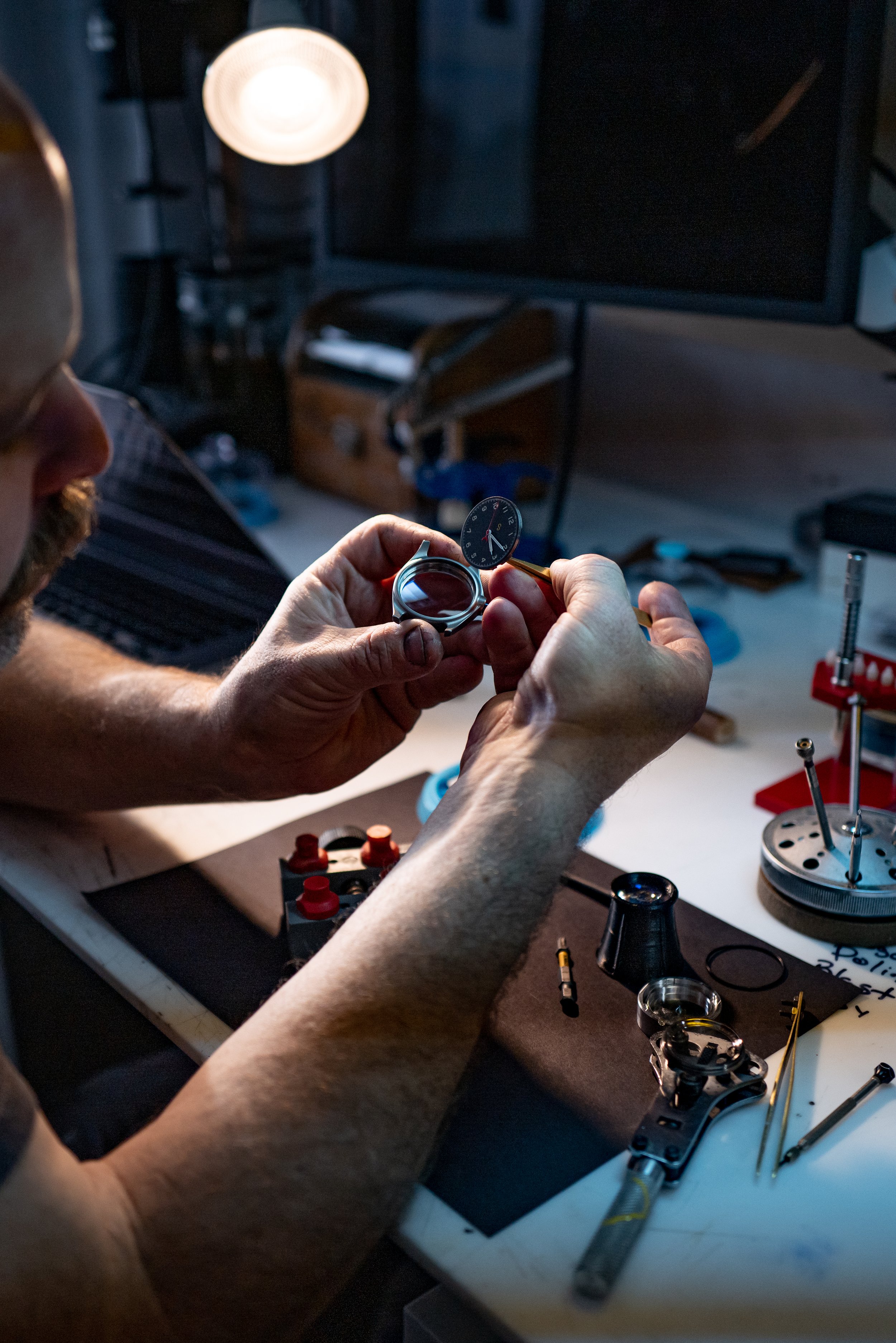

The Watchmaker At Work.

Photos by Jonah Markowitz